Transformers are vital components in electrical systems. They enable the efficient transfer of energy by adjusting voltage levels to meet specific needs. At the core of a transformer’s functionality are its core types and various components, each playing a crucial role in optimizing performance and reliability.

From the versatile toroidal cores to the space-efficient E-cores and the robust C-cores and O-cores, understanding these core types is essential for selecting the right transformer for any application. Also, components like mounting hardware, banding tools, inrush surge mitigators, and enclosures are critical for maintaining transformer efficiency, protecting against damage, and ensuring safe operation. A comprehensive understanding of transformer products is important for engineers and technicians to ensure optimal performance and longevity in electrical systems.

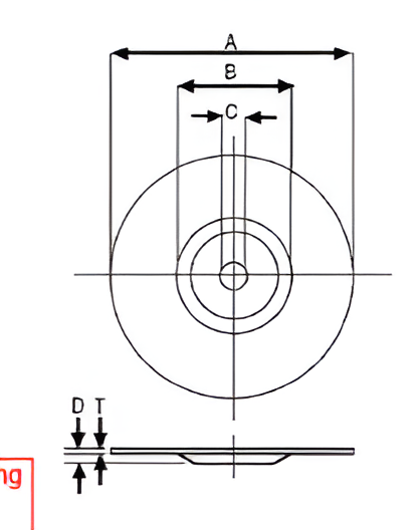

Toroidal Cores: Versatile and Efficient

Toroidal cores are ring-shaped and are widely used due to their efficiency in minimizing electromagnetic interference. They offer a compact design that reduces the overall size of transformers and enhances performance. The magnetic flux is contained within the core, leading to reduced losses and improved efficiency. Toroidal cores can be custom-made for specific applications, allowing for tailored performance and size adjustments.

Standard Toroidal Cores come in various sizes and materials and are suitable for general transformer requirements. Custom Toroidal Cores are designed for specialized applications where unique specifications are required, offering flexibility in design and performance.

Toroid Mounting Hardware: Secure and Reliable

In order to ensure the proper functioning of toroidal cores, appropriate mounting hardware is essential. Toroid mounting hardware includes brackets, clamps, and bases that secure the core in place, preventing movement and ensuring stable operation. Proper transformer mounting reduces mechanical stress on the core and maintains their alignment, which is critical for consistent performance and longevity.

E-Cores: Efficiency and Versatility

E-cores are named for their shape, resembling the letter “E” when viewed from the side. These cores are commonly used in transformers and inductors due to their versatility and ease of assembly. They provide a good balance between performance and cost, making them a popular choice for various applications.

C-Cores: Compact and High-Performance

C-cores are often used in applications where space is limited, but high performance is required. The design of C-cores allows for easy assembly and disassembly, which is beneficial for maintenance and repairs. They are known for their good magnetic properties and ability to handle high currents efficiently.

O-Cores: Balanced and Reliable

O-cores are ring-shaped and are used in transformers where balanced performance is crucial. Their design helps to maintain uniform magnetic flux distribution, which contributes to efficient operation. O-cores are often chosen for applications requiring reliable performance and consistent operation over time.

C-Core Banding Tool: Precision and Efficiency

The C-core banding tool is a specialized device used to secure C-cores during the assembly process. This tool ensures that the cores are tightly bound, which is critical for maintaining the integrity of the transformer’s performance. Proper banding helps prevent core movement and maintains optimal magnetic properties, which are essential for efficient transformer operation.

Transformer Inrush Surge Mitigator: Protecting Your Equipment

Transformer inrush surge mitigators are devices designed to protect transformers from the high current surges that occur when they are first energized. These surges can cause significant damage to both the transformer and connected equipment. Inrush surge mitigators help manage these initial surges, ensuring a smoother start-up and reducing the risk of damage. They are essential for maintaining the longevity and reliability of transformer systems.

Enclosures: Protection and Safety

Enclosures protect transformers from environmental factors such as moisture, dust, and physical damage. They also provide safety by shielding operators from electrical hazards. Enclosures come in various types, including metal, fiberglass, and plastic, each offering different levels of protection based on the application’s needs. Proper enclosures ensure that transformers operate reliably and safely in various environments.

Premium Transformer Cores and Components at Bridgeport Magnetics Group Inc.

Bridgeport Magnetics Group Inc. specializes in a wide range of transformer cores and components designed for superior performance and reliability. From versatile toroidal cores and efficient E-cores to space-saving C-cores and balanced O-cores, our products are engineered to meet diverse application needs. We also offer essential components like mounting hardware, banding tools, and inrush surge mitigators to ensure optimal transformer operation. With our commitment to quality and innovation, Bridgeport Magnetics Group delivers high-performance solutions tailored to enhance the efficiency and longevity of your transformer systems.